10 Stages: Transforming Single-Use Plastic Packaging into Recycled Polyester

Plastic waste destined for landfill can be reimagined as reliable recycled polyester, but that transformation requires a sophisticated technical process. So, how does single-use packaging evolve into a material trusted by the fashion industry for its durability and versatility?

This post unpacks the recycling process into ten straightforward steps, from collection and sorting to removing contaminants, followed by melt extrusion, pelletising, spinning, and finishing. Along the way, we highlight the checks that uphold quality and traceability. Dive in to discover where environmental gains are made, where challenges remain, and how to spot credible claims when considering recycled polyester in your fashion choices.

1. Why Single-Use Plastic Packaging Matters in Our Waste Streams

Start by identifying different packaging styles, such as flexible films, pouches, trays, caps, and layered materials, and linking them to recycling streams on the high street or through community and commercial schemes. Each stream varies in purity and processing needs: flexible films often arrive mixed and lightweight, whereas sturdier packaging tends to be easier to sort. Common sources of contamination—like food residues, sticky labels, or metal fastenings—can complicate recycling and sometimes result in materials being downgraded. To help close the loop, separate flexible films from rigid packaging where possible, empty and gently rinse items, remove obvious non-plastic features, and ensure materials are kept dry and clearly marked. These simple steps can make a real difference to recycling outcomes and support a more circular approach to waste.

Track the type of polymer, composition of collected bales, levels of contamination, and where feedstock originates to ensure consistency—making it easier for recyclers to accept more material. Routine spot checks on contamination and bale makeup help pinpoint where issues start, so collection points or frequency can be adapted as needed. Boost capture rates and material quality by working closely with local waste managers, high street retailers, and community groups. Clear signage and guidance for participants, alongside regular tweaks to the scheme based on transparent feedback, help keep the system on track and thriving.

2. Separate plastics mindfully by type, colour, and cleanliness

Sorting is a crucial step in recycling, separating packaging by polymer type, colour, and contamination to ensure quality and performance in the final material. Each polymer and pigment responds differently during processing, and additives can impact how the material is used. Technicians combine several approaches—manual sorting, trommels, air classifiers, float-sink tanks, and near-infrared optical scanners—to identify the unique properties of each piece. Optical systems, however, can struggle with dark or heavily printed items, so blending methods achieves more reliable results. Reducing contamination means removing caps, pumps, and metal parts, rinsing to tackle food residue, and stripping off problematic labels and adhesives where feasible. When loads are suspect—such as when PVC is mixed in, which can harm PET through corrosive by-products—they are kept separate to protect the integrity of the recycling process.

Colour and print play a pivotal role in shaping the potential of recycled polyester. Clear or lightly coloured PET often results in near-colourless material, opening up more possibilities for future use, while darker or heavily printed packaging may require decolourisation or produce tinted fibres, narrowing their application. Rigorous quality checks—using methods such as spectroscopy or melt flow analysis, alongside clear acceptance criteria and records of batch details—ensure only high-quality streams move forward. Separating lower-grade material and documenting traceability empower buyers to make informed choices about further processing. Reliable, transparent sorting not only boosts material yield and reduces unnecessary reworking, but also builds trust among those using recycled resources, underpinning more sustainable production across the board.

![{"image_loaded": true, "load_issue": null, "description": "A young man stands indoors, facing a clothing rack. He is holding a portable clothing steamer with one hand and a beige garment bag with the other. Behind him, several shirts hang on the rack. To the right of the man is a large woven basket with wooden handles, which contains white fabric.", "people": {"count": 1, "roles": ["individual"], "visible_demographics": "approximate young adult male, Black", "attire": "white button-up shirt over a muted ora](https://cdn.shopify.com/s/files/1/0416/7663/6312/files/image_loaded_true_load_issue_null_description_a_young_man_stands_indoors_facing_a_clothing_rack_he_is_holding_a_portable_clothing_steamer_with_one_hand_and_a_beige_garment_bag_with_th_a4f69a20-f871-4d95-b11d-c87e7157d263.webp?v=1768550585)

3. Strip Away Labels and Unwanted Materials for Pure Recycling

Contaminants such as paper labels, certain adhesives, printing inks, caps made from various plastics, metal clips, and organic residues can all disrupt the recycling of polyester. These substances may create unsightly specks or weaken recycled fibres if not removed properly. Techniques for tackling these challenges range from hands-on label removal and mechanical cleaning for smaller loads to advanced solutions like water flotation, specialised washing, and even laser or ultrasonic systems for the more persistent adhesives. Some approaches rely on chemicals or solvents, which can raise environmental and safety concerns, while methods such as mechanical or biological treatments aim to limit chemical use, though they may not always be as effective. Automated sorting technologies, including near-infrared and FTIR spectroscopy, optical sorters, and sink-float separation, help identify and remove unwanted materials early in the recycling process, protecting the purity and quality of the final product. By addressing these hurdles, the industry moves closer to a truly circular, sustainable future.

Effective recycling starts at the source. Carefully rinsing out residues, removing caps and metal fittings, and keeping flexible packaging apart from rigid PET containers can make a real difference in the quality of recycled polyester. Recycling facilities should capture and treat wash water, recover label fibres for reuse in paper where possible, and always ensure staff use proper protective gear and ventilation when handling cleaning agents. Checking for leftover contaminants using methods like melt filtration and colour testing helps ensure only clean material is processed. Batches with ongoing contamination should be reprocessed or set aside, avoiding defects in new polyester yarn and supporting more reliable recycling from start to finish.

4. Clean and dry for a fresh foundation

To ensure materials can be reused responsibly, it's essential to start with careful sorting. Remove any non-recyclable elements and separate out items that could disrupt the recycling process. By breaking down the material and using a considered washing sequence, we help prevent contamination and support higher-quality recycling outcomes. This approach plays a vital role in keeping resources in use for longer and reducing environmental impact—a reminder of the positive steps we can take towards a more circular and sustainable future.

When tackling labels and adhesives in the recycling process, it’s vital to use cleaning methods suited to the material—alkaline or solvent-compatible washes, paired with controlled temperature and agitation, help release stubborn residues. Once separated, density, flotation, or careful manual sorting ensures these fragments are properly removed. Extracting water with mechanical pressing or centrifuge, followed by low-moisture drying, is crucial, as excess moisture can compromise recycled polyester by breaking down its structure. Throughout, it’s essential to capture and manage wash water and microplastics using screens, hydrocyclones, and settling tanks, recovering useful material and treating effluent responsibly. This approach not only preserves material quality but also limits environmental impact, keeping the recycling stream as clean and effective as possible.

5. Shred material into uniform flakes

When processing recycled materials for sustainable trainers, aim for flakes of around 4 to 10 mm in size with a natural, plate-like form. Smaller flakes can boost efficiency in washing and melting, though it's important to avoid excessive fines that may cause blockages. It's crucial to remove any non-polyester materials, both before and after shredding. Use magnetic and optical sorting to help eliminate metals, PVC, and mixed plastics, and inspect for labels or closures that could impact quality. Adjust equipment settings, such as blade gap and feed rate, to ensure flake consistency, while monitoring performance to keep operations smooth and eco-friendly. Keep an eye on temperature control during shredding to avoid unwanted melting, helping to maintain the integrity of each recycled component. This approach supports a cleaner process and contributes to more responsible, sustainable fashion.

Once materials are shredded, advanced sorting methods can help separate out unwanted fragments and contaminants, ensuring only high-quality flakes progress further. Moisture is reduced using specialised equipment, supporting the integrity of the recycled polyester. Consistent quality checks—including measuring flake size, monitoring moisture, and screening for impurities—are crucial to maintaining high standards. Tracking attributes like intrinsic viscosity and melt flow allows for fine-tuning the recycling process, helping ensure the resulting polyester retains the strength and vibrant colour required for responsible, stylish fashion.

Opt for a recycled‑content layer that supports circular fashion.

6. Refine Materials for Purity and Sustainability

Before processing recycled materials, it is essential to ensure all flakes or pellets are thoroughly dried and free from any rigid contaminants or metal fragments. Moisture can compromise the strength and quality of the final product, so careful preparation is key. Selecting the right processing equipment is equally important: a twin-screw extruder or a single-screw system with enhanced mixing capabilities can help achieve consistent cleanliness and effective blending. Balancing process time and intensity supports the removal of contaminants while maintaining material integrity, and a melt pump ensures smooth, reliable operation throughout. This careful approach safeguards both performance and sustainability in every step.

Begin recycling by using progressive filtration: start with a coarse screen to capture larger non-meltable materials, then move to finer filters to remove gels, inks and particulates. Employ continuous filters to keep the process efficient and uninterrupted. Incorporate devolatilisation and vacuum venting to extract water, low molecular weight substances and volatile impurities, helping to reduce unwanted colour, odour, and further breakdown of the material. Throughout the process, monitor temperature, pressure, torque and colour to maintain quality, and check intrinsic viscosity regularly for consistency. If the recycled material shows considerable quality loss or persistent contamination, integrate approved additives to restore performance. Always ensure that any waste or contaminants are managed responsibly and returned through a controlled, transparent recycling system.

7. Transform Recycled Polyester into Eco-Friendly Pellets

In recycling processes, cleaned plastic flakes are transformed using extruders, where continuous melt filtration ensures impurities are removed before the material is shaped into strands or cut at the die face. These are then cooled, either in water or air, and separated by size to create uniform pellets. Careful control of temperature, pressure, and filtration is essential, as well as monitoring the viscosity of the material after extrusion, to ensure the final pellets maintain their strength and quality. This meticulous approach is crucial for producing reliable, high-performance materials that can be repurposed for new products, supporting a circular and sustainable approach to manufacturing.

For those passionate about ethical fashion, understanding the journey of sustainable materials is essential. Consistent quality matters: characteristics such as length, diameter, density, moisture content and colour all play a role in creating durable, high-quality fibres. By carefully sampling batches, screening for impurities, and keeping a clear record of sources and quality checks, it becomes possible to ensure that each step aligns with responsible manufacturing. Thoughtful storage—using sealed, moisture-proof containers and rotating stock to maintain freshness—protects materials and helps prevent defects. These conscious choices support a supply chain that values resilience, transparency and sustainability, at every stage.

8. Transform Molten Polyester into Distinctive Sustainable Yarn

Melt spinning is a method used to transform recycled PET into strong, continuous fibres, supporting a more sustainable approach to textile production. By carefully managing temperature and filtration during the process, producers help ensure these fibres are consistent and free from impurities. This level of precision not only improves the quality and durability of the end material, but also demonstrates how recycled resources can be given new life in high street fashion, reducing waste and promoting responsible choices in the industry.

The structure and quality of yarn are shaped by choices in spinneret design and filament count. Opting for finer filaments results in a softer touch and improved drape, ideal for garments that move with you, while coarser filaments provide a more robust texture suited to hard-wearing pieces. The drawing and heat-setting process then helps stabilise the yarn, refining its strength and resilience. When it comes to creating different textures and finishes, techniques like false-twist texturising add stretch and a sleek look, while air-jet methods offer a light, wool-like feel, and crimping brings warmth and plushness. For those working with recycled materials, it's vital to assess quality—checking for consistency, colour, and unwanted particles—before blending and refining to ensure every strand meets the high standards of sustainable fashion. Regular checks throughout production maintain yarn integrity, so the final product delivers both style and substance.

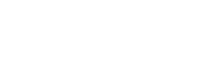

9. Transform Yarn into Fleece and Refine with Finishing Touches

Filament yarns are carefully processed into a fleece by opening and carding the fibres, then layering and shaping them to achieve the desired feel and performance. Adjustments in fibre length, direction, and density create different levels of loft, drape, and insulation, allowing for versatility across a range of uses. To bring the material together, producers use methods such as needle-punching for extra strength and bulk, hydroentanglement for a softer touch and greater breathability, thermal fusion for stable structure, or stitch-bonding for targeted durability. Each method affects the final fabric’s character, from softness to resilience. Selecting the right approach means striking a balance between durability, comfort, and sustainability—empowering conscious makers to create materials fit for purpose.

Finishing processes can transform the look, feel, and durability of fleece, but it’s important to consider their impact on both wear and sustainability. Treatments like brushing or peaching affect surface texture, while water-repellent coatings and anti-pilling finishes offer added protection. However, these choices can also influence recyclability and the release of microfibres during washing. When working with recycled materials, uneven dye uptake can be a challenge, so options like solution-dyeing at the polymer stage or careful piece-dyeing may be favoured. It’s best practice to pre-sort and filter recycled fibres, and to run small dye trials to ensure consistent colour and lasting vibrancy. Throughout development, manufacturers should assess abrasion resistance, pilling, insulation, and microfibre shedding using recognised tests. Prioritise finishes that support long-term wear and environmental responsibility, using standardised data to choose processes that balance performance with a lower impact on the planet.

10. Embrace Recycled Polyester and Champion Transparent Impact Tracking

Establish transparent targets for recycled content and product performance, ensuring suppliers provide credible documentation for post-consumer recycled materials. Confirm that recycled polyester meets quality standards, such as durability and colour fastness, through independent laboratory assessment. Employ advanced techniques, including material identity checks, to maintain integrity across the supply chain. Advocate for regular third-party review and robust oversight at each stage of the reprocessing journey, empowering buyers and designers to make informed, responsible choices for a more sustainable fashion landscape.

Embrace a transparent approach to materials by documenting each step in the supply chain. Use traceable methods—such as digital batch IDs, QR codes, or product passports—to ensure every finished piece can be tracked from origin to creation. Assess environmental impact with a life cycle perspective, applying recognised tools to measure carbon and water footprints. Share results in clear terms, such as the amount of CO2 equivalent per kilogram of fibre, water usage, the proportion of virgin polyester avoided, and any microfibre loss, while openly explaining your methodology so comparisons are meaningful. When designing for recyclability, prioritise single-fibre fabrics and trims that can be easily separated. Steer clear of treatments and material mixes that make recycling difficult. Clearly label garments with verified recycled content and traceability codes, and communicate what happens at the end of a product’s life to demonstrate how recycled fibres are recovered and reused.

Transforming single-use packaging into dependable recycled polyester is a meticulous process, rooted in collection, sorting, cleaning, melt processing, and fibre finishing. Every stage is essential to minimising contamination and preserving material integrity. Through rigorous checks on cleanliness, intrinsic viscosity, and traceability, post-consumer waste can be given a new lease of life as high-quality yarn—proving that yesterday’s packaging can become tomorrow’s essential gear for the high street.

Use these ten stages as a practical guide when evaluating environmental claims. Seek clear information from suppliers, such as traceability records and sustainability documentation. This approach shines a light on key trade-offs, reveals where true environmental gains are made, and empowers buyers to make choices that support a circular economy for plastics.